When the Last Tree is Cut Down, the Last Fish is Eaten, and the Last Stream is Poisoned, White Man will Realize That Money Cannot be Eaten!

One day everything will be cheaper than water ®

SUBJECTS TO CONSIDER WHILE SELECTING TREATMENT TECHNOLOGY:

Low energy cost

Low odor and noise

Maintanence ease

Sustainable and smaller carbon footprint

WHY DID KFW, GERMAN INVESTMENT BANK, GAVE THE FUNDS TO STATE OF GEORGIA UNDER ONE CONDITION?

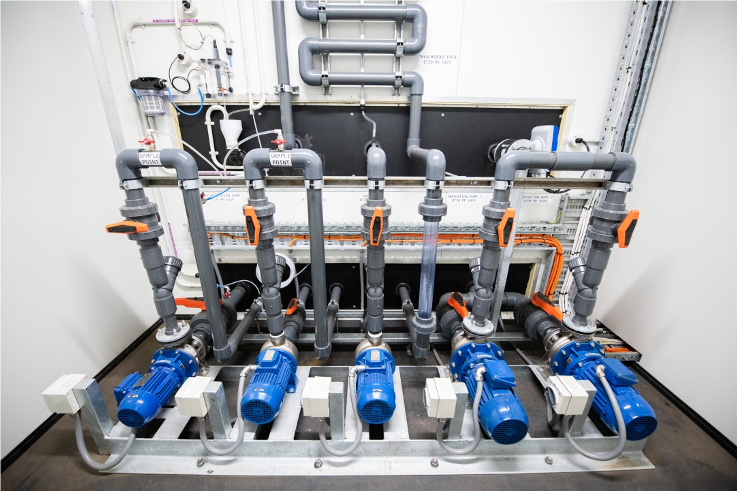

Advantages of the process:

- Low Energy

- Safe operation with low maintenance

- No Process Engineering required

- Easy and stable operation with little supervision

- Space-saving modular system

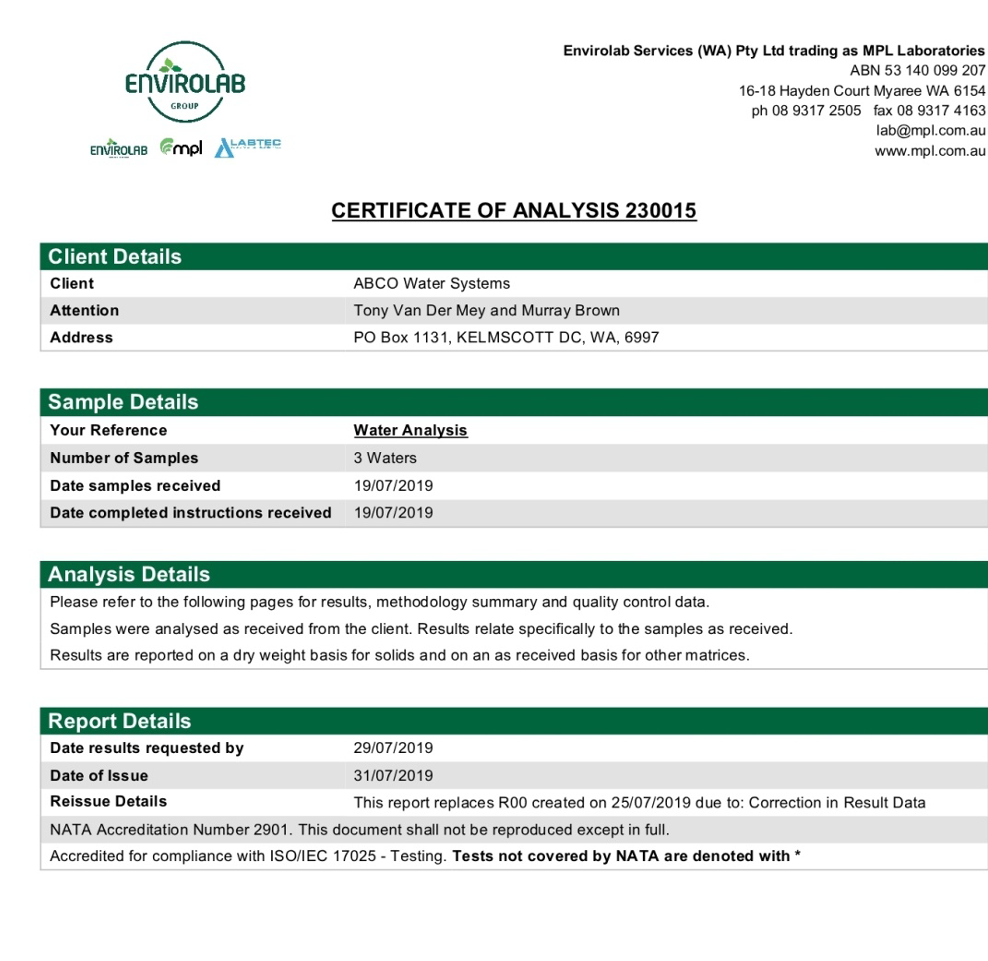

ABCO AUSTRALIA ANALYSIS RESULTS

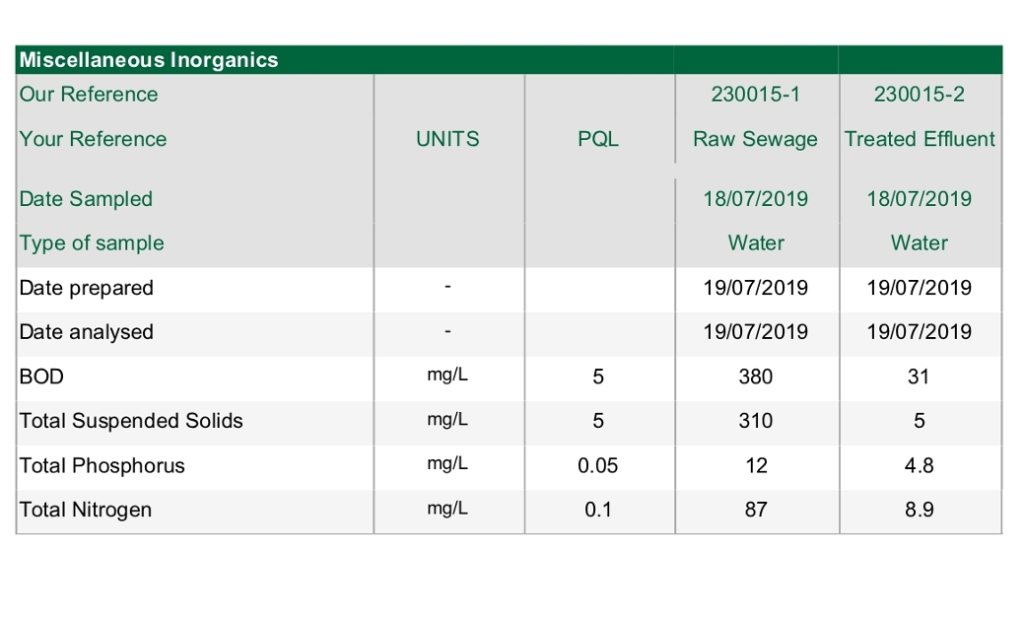

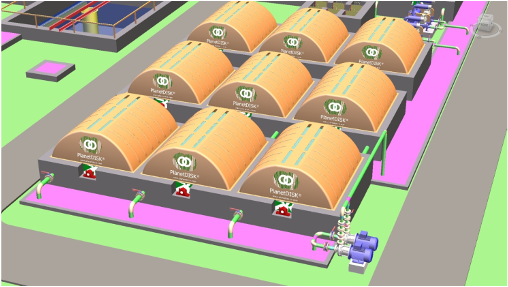

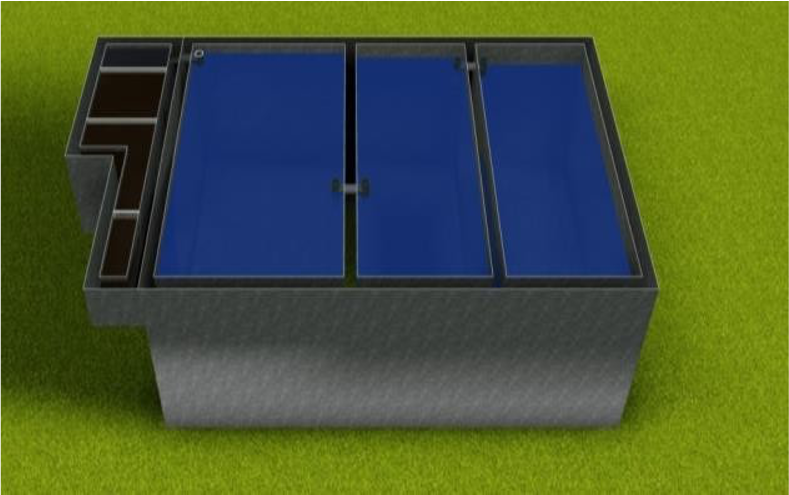

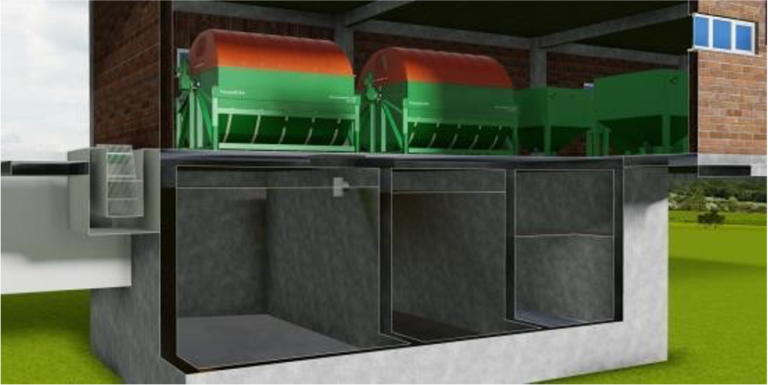

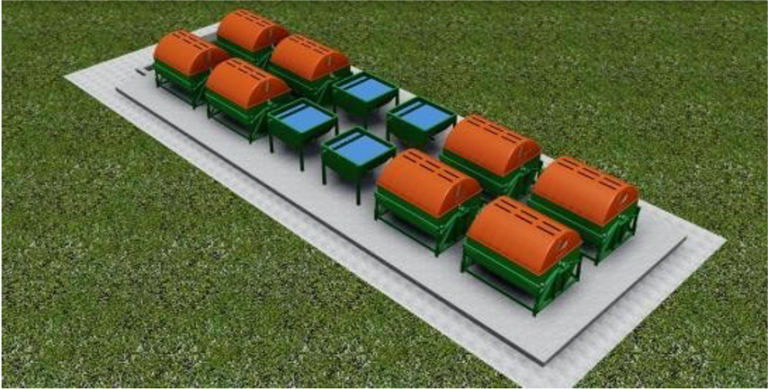

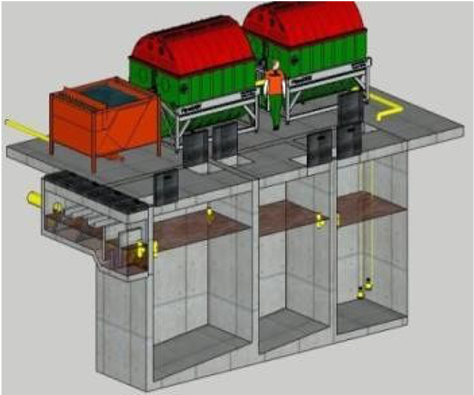

3D RBC WASTEWATER TREATMENT PLANT MODEL RESULTS

3D RBC WASTEWATER TREATMENT PLANT MODEL RESULTS

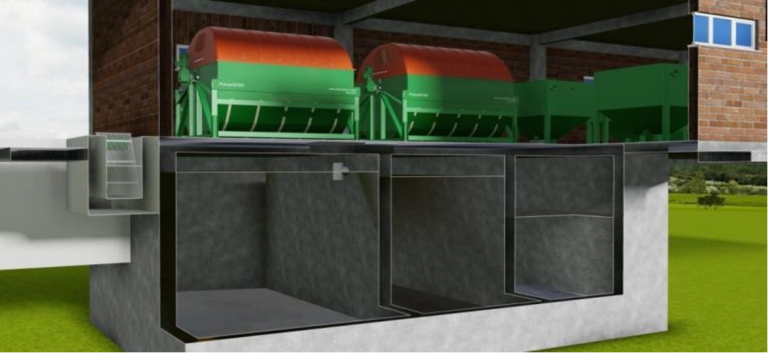

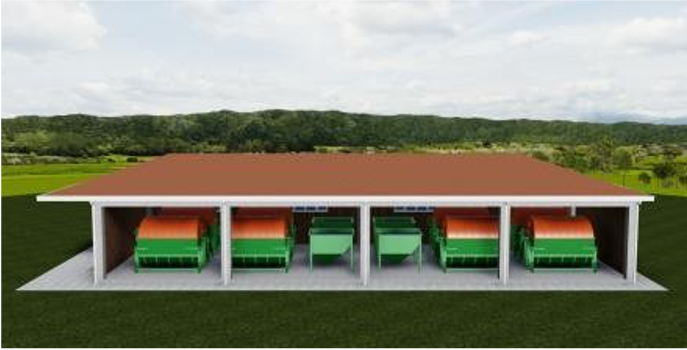

A TYPICAL FACILITY FOR 1500-3000 PEOPLE

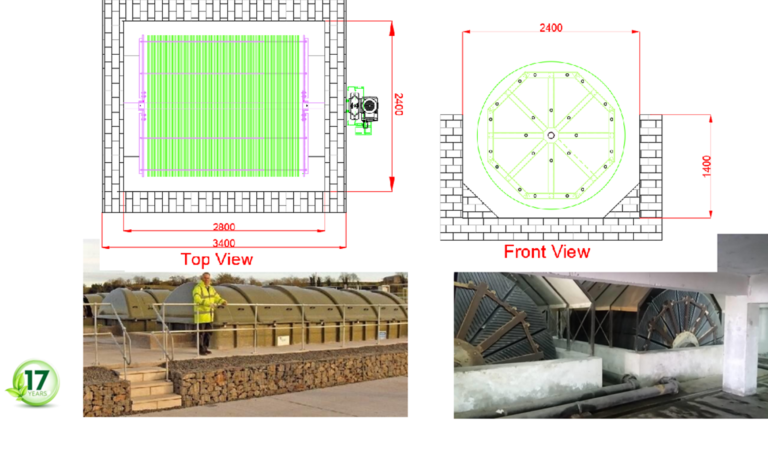

SIMPLE BUILDINGS TO COVER RBC UNITS

SIMPLE BUILDINGS TO COVER RBC UNITS

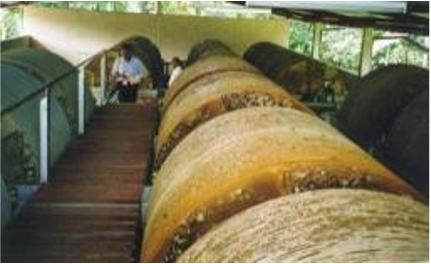

ROTATING BIOLOGICAL CONTACTOR SYSTEM IN THE WORLD (OTHER INTERNATIONAL MANUFACTURERS)

ROTATING BIOLOGICAL CONTACTOR SYSTEM IN THE WORLD (OTHER INTERNATIONAL MANUFACTURERS)

The pictures below are all from England. Most W. European countries prefer Rotating Biological Contactor.

ROTATING BIOLOGICAL CONTACTOR SYSTEM IN THE WORLD

World’s largest biodisc application is in North Carolina;

750.000 PE/day capacity.

ROTATING BIOLOGICAL CONTACTOR SYSTEM IN THE WORLD

Another giant RBC application is in Orlando Florida with a capacity of 460.000 PE capacity.

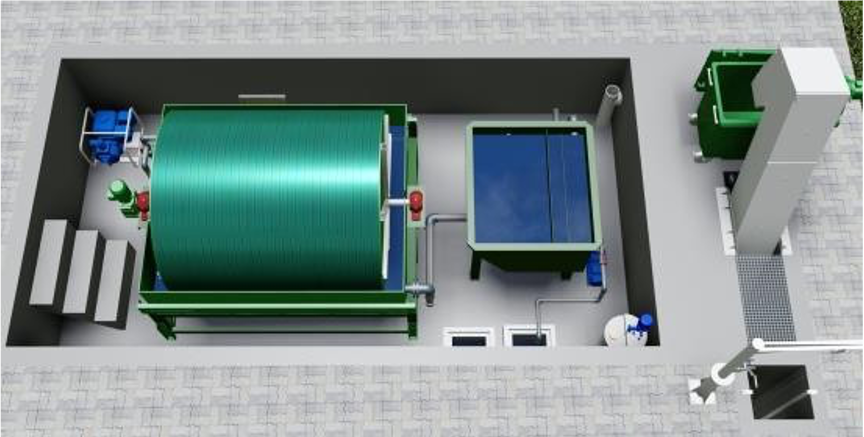

ROTATING BIOLOGICAL CONTACTOR THE WORKING PRINCIPLE

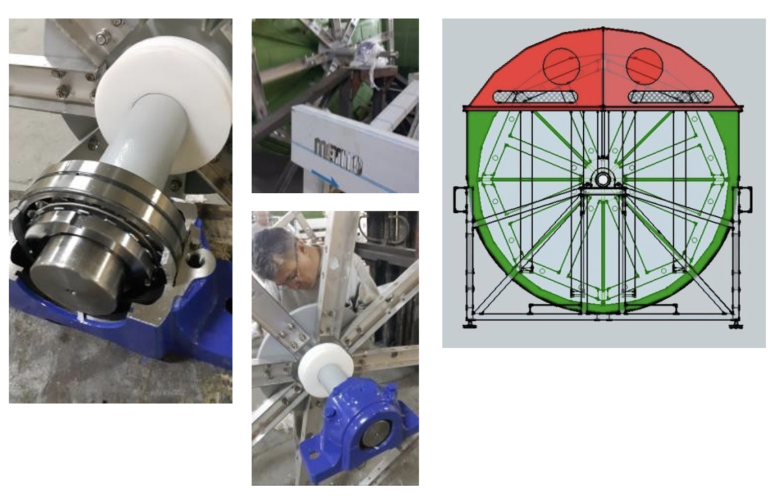

Unit is a fixed film biological Sewage Water Treatment system consisting of circular disks made of non-corrosive, Polypropylene (PP), mounted on a solid steel shaft rotating at a speed of less than 4 rpm (watch in presentation mode for animation).

During the rotation, 40% of the disks are immersed in wastewater and the rest are in contact with air.

RBC process is widely used in the world since 1960s. Due to its simplicity in operation and energy saving mechanism, its popularity is continously growing.

Simplicity is the ultimate sophistication.

Leonardo da Vinci

ROTATING BIOLOGICAL CONTACTOR METHOD

- GRP (fiberglass) body that will protect the system from corrosion;

- Virgin Polypropylene 1-piece Discs (PP) which will last for years without any degradation; 2050 mm diameter, at least 1.5 mm thickness.

- 85 mm diameter Solid Steel shaft – chromium coated and/or epoxy painted- AISI 1045

- All deep galvanized metal parts to last for years against corrosion. Stainless Steel is optional.

TECHNICAL DATA

Treatment Plant Capacity:

10-4000 m3/day

Each unit capacity = 40-80 m3/ day depending on BOD load and effluent and influent characteristics

Each unit power requirement= 0.37 kW

Delivery & Packing

Unit dimensions = 2300mm (W)x3250mm (L)x3000mm(H)

Empty weight = 2000 kg

Full operational weight = 7500 kg

3 pieces MX1 units fit in 40ft High Cube shippingcontainers

WHY US ?

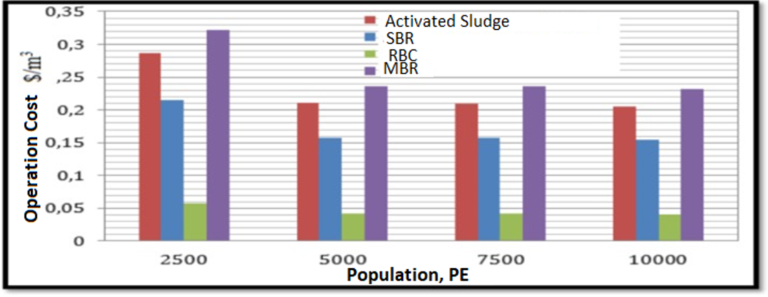

- Activated Sludge (A.S.)

- Sequencing Batch Reactor (SBR)

- Rotating Biological Contactor (RBC)

- Membrane Biological Reactor (MBR)

- The wastewater treatment technology with the smallest carbon footprint is RBC

One day, everything will be cheaper than water.